EPC Projects

- Collection of Client Feed Data

- Perform Detailed Engineering

- Issuance of Construction Drawings

- Authority Approval

- Selection of System from Qualified Vendors

- Tanks – Piping – Utilities

- Electrical, Instrumentation, Automation

- Civil & Structure

- Process Equipment Installation

- Testing & Commissioning

Shutdown Projects

- Target-oriented, disciplined & responsible team

- Shutdown planning to level #5

- Big-size critical projects

- Coordinating with 3,200+ vendors

- Right tools arrangement from around the globe

- Daily Planned vs Actual report

- Non-compromised safety

- High-speed communication system

- Own control room to monitor shutdown progress

- Leadership in coordination meetings

- From plan to realization – An expert guide in the shutdown optimization process

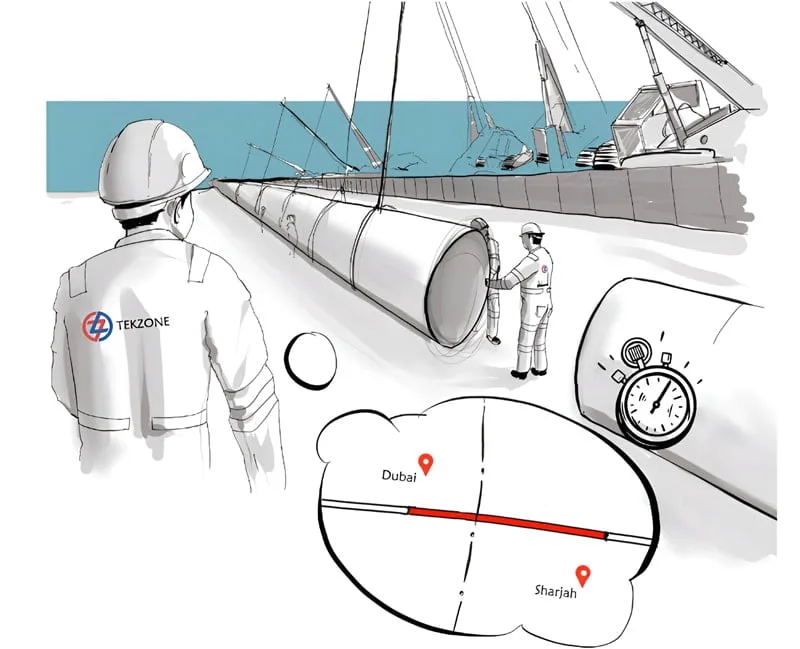

Cross-Country Pipeline

- Engineering & Design

- Steel Pipes of All Sizes

- 3LPE, Insulation, FBE Coated Pipelines

- Road/Water/Mountain Crossings

- Dewatering / Sheet Piling

- Control Cables / Cathodic Protection

- De-magnetization

- Long Radius Cold Bends

- Hot Tapping & Pigging

- Vaporizer / Liquid Nitrogen Purging

- Cold Cutting

- Automatic Welding

MLA & Dry Conveying

- Design & Sourcing of MLA

- Structural Assessment

- Foundation Design & Construction

- OEM Integration & Support

- System Integration

- Overhauling & AMC

- Commissioning with OEM Support

- Marine Activity Support

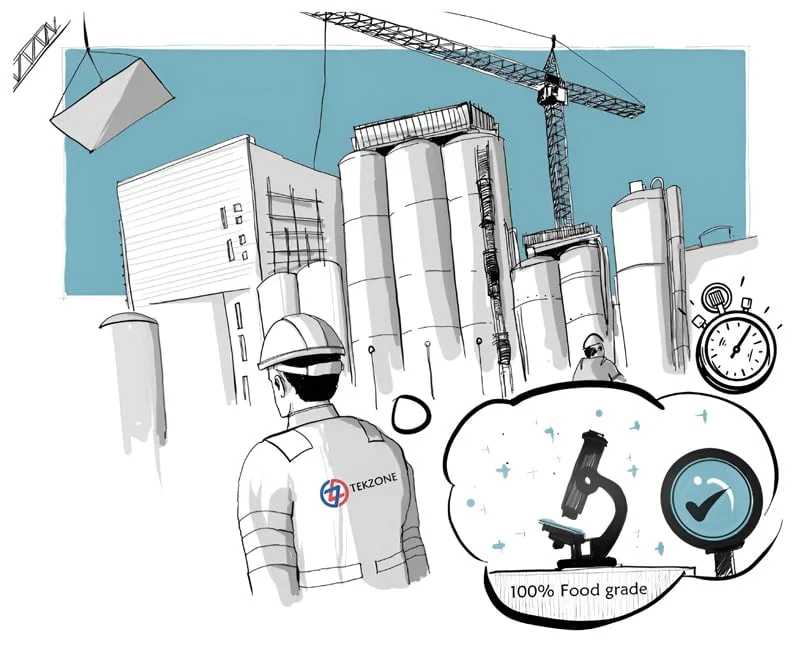

Process Tanks & Piping

- Factory produced Stainless Steel Process Tank

- Jacketed / Insulated Tank

- Spray Balls for CIP

- Agitator / Mixers

- Magnetic View Glass

- Hygiene Manhole

- Hygiene Pumps & Valves

- Access Platform

- End to end transportation

- Heat Tracing, Insulation & Cladding

Pontoon & Fuel Dispensers

- Concrete / GRP / Aluminium Pontoon

- Gangway / Access Bridge

- Access Bridge

- Fuel Dispensers

- Double Wall Marine Fuel Piping

- Operator’s Kiosk

- Marine Piling

- Barge Arrangements

Factory Relocation

- Schedule planned to PS level #4

- Full system photography & videography

- Tagging of all instruments & machines

- Production line by line dismantling

- Packing sea/road worthy

- End to end logistics

- Non-interrupted installation work

- Commissioning assistance

- System matching with new layout

- Minimalistic down time of production line.

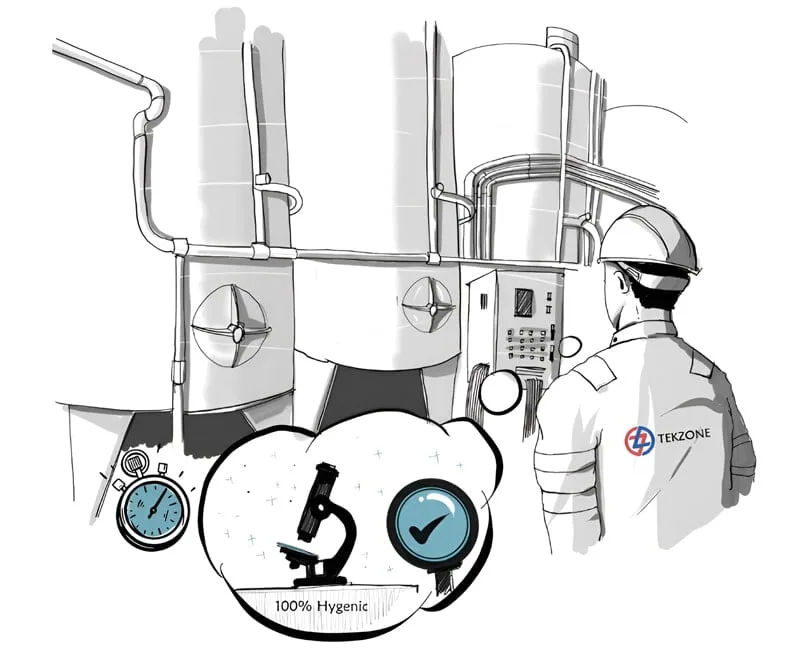

Hygienic Process Factories

- Hygienic Piping – SMS / DIN standard

- Valve cluster - Alfa Laval / GEA

- CIP System

- Control & Mix proof Valves

- Actuator with THINKTOP

- Pickling & Passivation

- GRP/FRP gratings

- Steam & Chilled Water System

- Electrical, Instrumentation & Controls

- Clean Room with HEPA System

- Hygienic Flooring & Coating

Frequently Asked Questions

Tekzone is ranked among the top EPC contractors in Dubai for its comprehensive, end-to-end solutions in engineering, procurement, and construction across various industries, including oil and gas and industrial automation.

Tekzone specializes in high-stakes industrial and plant shutdown projects in the UAE, providing advanced planning, safety compliance, and seamless execution with minimal downtime.

Yes, as expert cross-country pipeline contractors in the UAE, Tekzone provides full-service pipeline installations with specialized techniques for challenging terrains.

Yes, as leading factory relocation contractors in Dubai, Tekzone provides end-to-end relocation services, including disassembly, logistics, and reinstallation with minimal production interruption.

Yes, Tekzone done several plant automation using PLC, SCADA and HMI Systems of Siemens, Rockwell or Wago.

Yes, Tekzone completed several projects for Electrical distribution system from High voltage connection to the Transformer followed by LV Connection Works such as installation of SMDBs, MDBs DBs and Capacitor Banks.