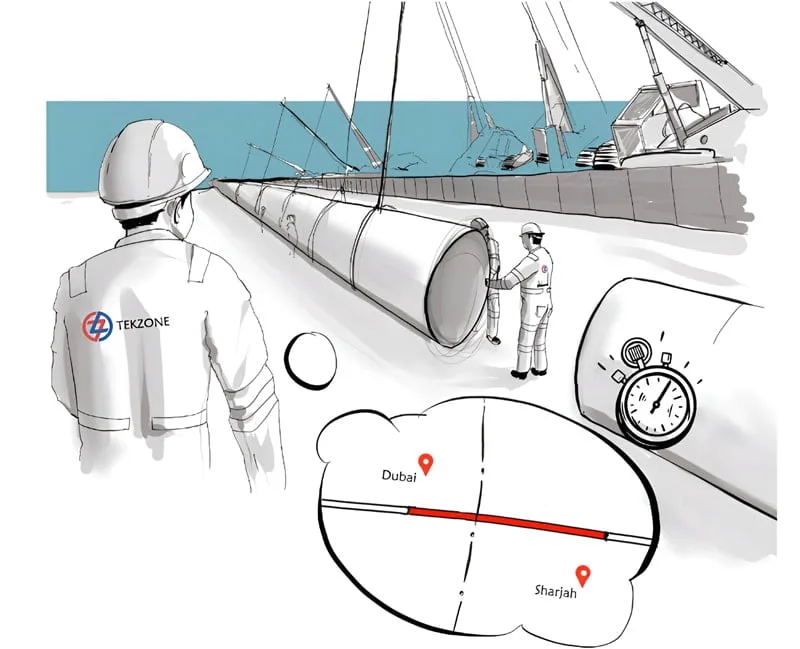

A cross country pipeline is a long-distance pipeline system designed to transport fluids—such as crude oil, natural gas, water, or chemicals—across vast geographic areas. These pipelines typically run over varied terrains including deserts, hills, rivers, and populated regions, connecting production sites with refineries, processing facilities, storage terminals, or distribution centers. We specialize in the design, installation, and commissioning of cross-country pipeline systems for oil, gas, water, and industrial applications. Our turnkey solutions ensure reliable product transportation over long distances, across deserts, mountains, and urban zones.

Cross Country Pipeline

- Engineering & Design

Comprehensive pipeline engineering and route design solutions, incorporating terrain analysis, stress modeling, and compliance with international codes and client specifications. - Steel Pipes of All Sizes

Supply and installation of carbon steel pipes in various diameters and thicknesses to suit oil, gas, and water transmission applications. - 3LPE, Insulation, FBE Coated Pipelines

Pipelines coated with 3-Layer Polyethylene (3LPE), insulation jackets, and Fusion Bonded Epoxy (FBE) to ensure corrosion resistance and thermal protection in harsh environments. - Road/Water/Mountain Crossings

Execution of complex crossings under roads, rivers, and mountains using trenchless technologies like HDD, boring, and microtunneling, ensuring minimal surface disruption. - Dewatering / Sheet Piling

Groundwater control through dewatering and structural soil support using sheet piling for safe excavation and trench stability in water-logged or loose soil conditions. - Control Cables / Cathodic Protection

Installation of control cables for monitoring systems and cathodic protection systems to prevent corrosion and extend the service life of buried pipelines. - De-magnetization

Application of pipeline degaussing (de-magnetization) to neutralize magnetic fields that can interfere with welding quality or pipeline operation. - Long Radius Cold Bends

Fabrication and installation of long-radius bends using cold bending techniques to maintain flow efficiency and reduce the number of welded joints. - Hot Tapping & Pigging

Live pipeline connections through hot tapping without shutdowns and internal cleaning/inspection using pigging systems to maintain flow integrity. - Vaporizer / Liquid Nitrogen Purging

Use of liquid nitrogen and vaporizers for inerting and purging pipelines to ensure safe working conditions during repairs or commissioning. - Cold Cutting

Precise, spark-free cutting of pipes using cold cutting techniques—ideal for hazardous environments where fire or heat must be avoided. - Automatic Welding

High-quality, consistent welds achieved through automatic and semi-automatic welding systems, improving speed, productivity, and safety in pipeline fabrication.

Tekzone is among the leading cross-country pipeline contractors in the UAE, managing end-to-end pipeline installations for oil factories pipeline contractors. We handle various terrains with advanced coatings and protective measures, ensuring durable and safe pipelines for oil, gas, and other industries.

For inquiries,

contact us at +971 4 333 6844 / +971 55 990 5397

or email enquiry@tekzoneme.com